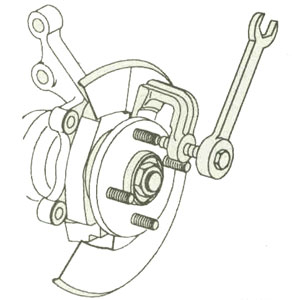

I'm trying to replace a lug nut stud on my 02' Buick Century and there doesn't seem to be any way to replace it without removing the hub.

I would have thought that GM engineers would have left an indent in the hub so that the stud could be pushed back/inserted without removing the hub.

Is there any trick to doing this that I'm missing?

I would have thought that GM engineers would have left an indent in the hub so that the stud could be pushed back/inserted without removing the hub.

Is there any trick to doing this that I'm missing?