Ron-Indy,

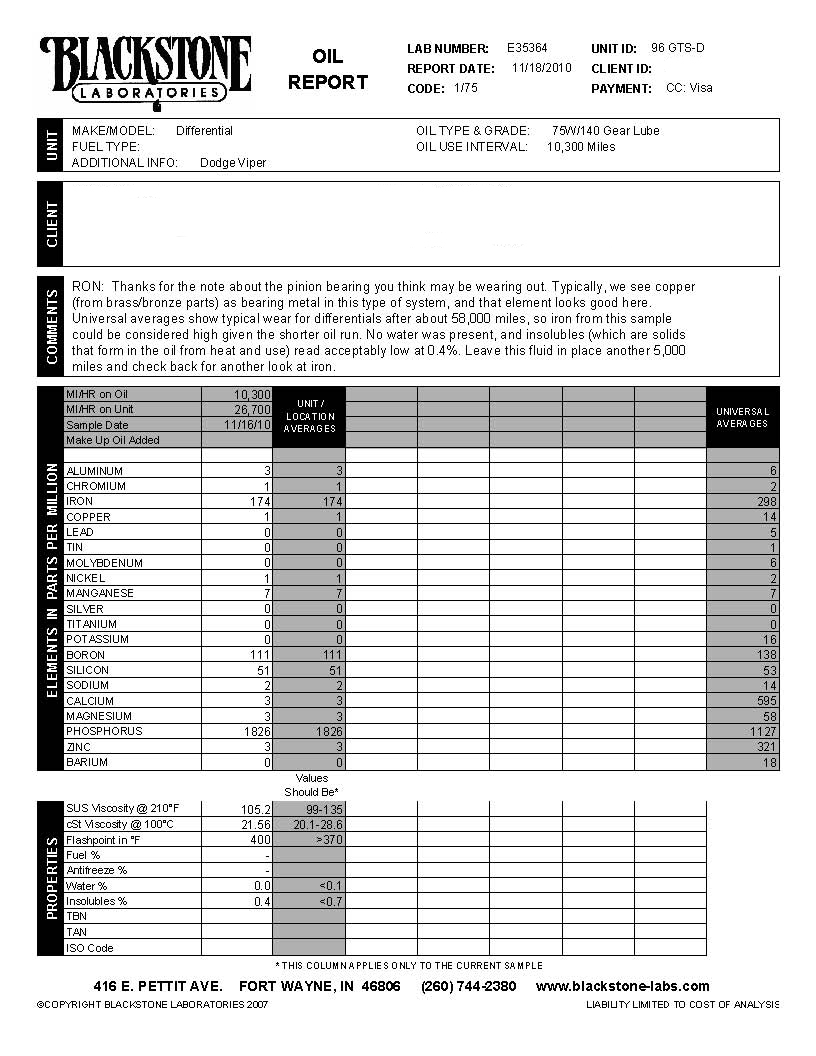

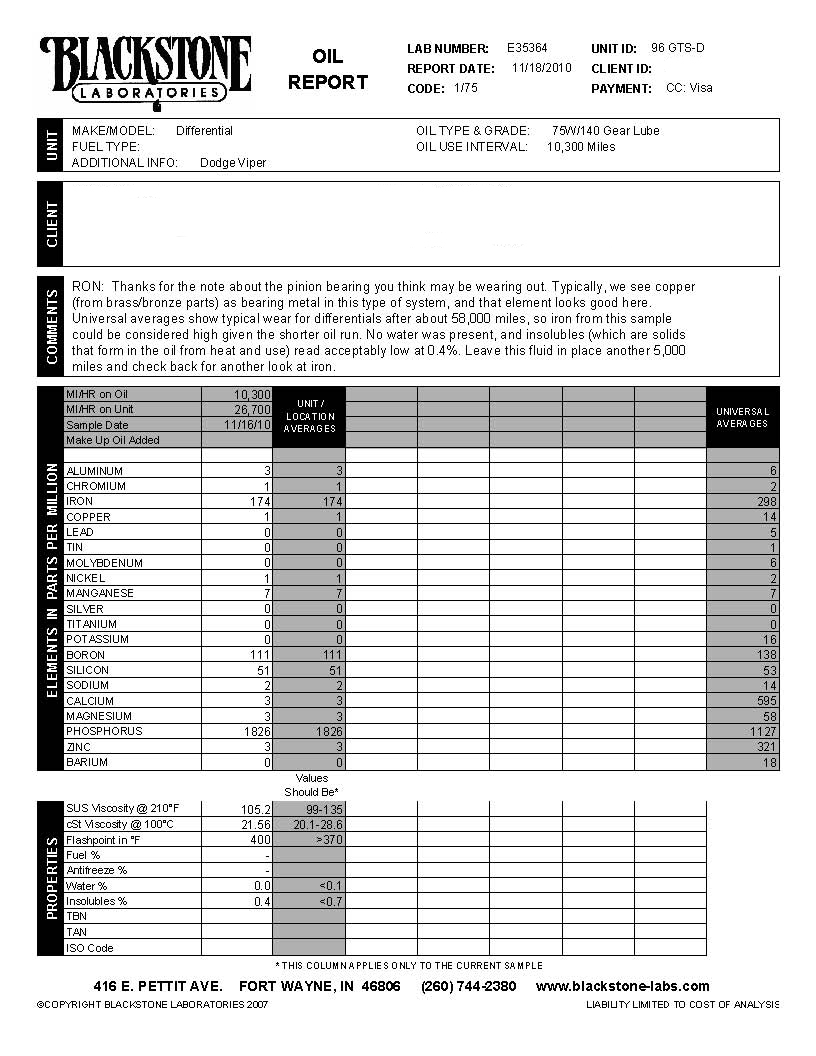

Thanks for the update. I am sticking with my original theory that the rear has sheared this oil down, accelerating wear and causing excess noise.

But if other Viper owners are saying it's not common, perhaps your diff was not properly set-up by the factory? Perhaps it's not shimmed correctly and that is causing the shearing, extra wear and noise? All these symptoms seem to go hand in hand.

In the short term, I would change the oil and see how quickly the noise comes back ... say another 6,000 - 7,000 miles? That will buy you some time to find someone who really knows their Dana 44 diffs to open up the rear end and check to see if it is set-up properly.

I'd switch oils ... but that's up to you. If other owners have good luck using the same stuff, I doubt switching oils is going to make a world of difference.

Sweet ride, by the way. The 1st Generation hard top Vipers are some of the most gorgeous cars ever made ... taking after the 1965 Shelby Daytona Coupes, of course.