While I agree with some of the RL comments from the quote, let's not just bow out of ignorance and presume all is as he (Roy, the RL rep) states.

I do agree that different chemistry packages affect the host equipment differently; always been a fan of multiple UOAs for trending and ranges. However, some of the things he (Roy) states is just plain wrong, or misleading.

For example, UOAs based upon spectrometry are generally reliable from 1-5um, not 3-5um as he states. (He is basically stealing away 50% of the applicable range in that one statement). A range of 3-5 um would be so small that it would be nearly worthless to view the results. Further, while I do agree that spectrometry is limited to around 5um on the upper end, other methods can only tell you size, but not composition of the wear metals. (For example, particle count analysis can show you size ranges and contamination (occurrence) rates, but not what the actual metals are; that's why many look at gas spectrometry).

Also, he states that UOAs only see 15-20% of the total wear? So, if there is 32ppm of Fe (such as the OPs UOA) in a claimed 3-5um range (all according to Roy's claim of spectrometry limits), then can we presume that there are 192ppm more Fe floating around, that is in the "non-visible" range? I call a bovine-poo on that! I think what we need to analyze is the difference between what is known to exist, versus what is possible to exist. Did he mean that a UOA can only see 15-20% of the "typical" contamination range? If so, that would mean that the "normal" size range of particles would be only 15um. How did I come up with that? His range (3-5um, inclusive = 3um) multiplied by a factor of 5 (20% x 5 = 100%). So I'm to believe that a particle count analysis would only discover a total size range of 15um? Wrong! Any way I look at it, his numbers don't work out.

Also, and perhaps it's just a mistake on his part, but I take exception to his comment about "... while adhesive wear is many orders of magnitude greater than the chemical wear, ..." This indicates that he has no comprehension of math. One "order of magnitude" is a factor of 10 (ten); so if he states the spectral analysis is effective in a range of 3-5um, and you multiply by "many orders of magnitude" to infer the size of the "adhesion wear", that would make the particles 3000-5000um or larger, floating around from "adhesion wear"? I hardly think so! Even ONE order of magnitude would present particles 30-50um in size; something that large would be caught by the main full-flow filter the first time around. I believe what he's trying to state is that some wear is seen with spectrometry (I agree) and some wear is seen with particle count analysis (I agree). But you cannot use one to supplant the other. They can be complimentary in nature, but not interchangeable in nature.

UOAs show us both the occurence rate (how much) and composition (what type), but in an admittedly narrow range (1-5um). PCs show us larger particle existence for various sizes, but nothing about where they came from. Small particles happen all the time; large ones happen infrequently, and in fact, the larger they are, the much less frequent they are. That is the realistic view of both UOAs and PCs. In essence, we are using UOAs to view trends BEFORE they become catastrophic events! If you have high "chemical wear", how in the world can you seperate out the "noise" from the truly terrible? Here's an example of how this can be misleading. Suppose you run "normal" oil and average 10ppm of Fe for several successive UOAs. Suddenly, you jump up 10ppm to a total of 20 ppm on your next UOA; you just experienced a 100% increase, and you'd have cause for concern. But if you were typically in a "high chemistry wear" pattern using RL oil, and have 35ppm as "normal", and then you jumped up 10ppm from some "event", you would only see that as a 35% increase, and possibly pay little heed to it. See how the concept of using "high chemical wear" as a base line can be misleading?

I also take issue with his comment of "soluble metals"; the traditional metals we look for in UOAs (Fe, Cu, Al, Pb, Cr, etc) are NOT soluble in the applications we are used to looking at. I guess it's a technical point, and maybe he was just in a hurry and misstated his position, but these are not dissolved into the host fluid. They are broken down into various sizes and co-exist with the fluid (oil), but they don't dissolve into the fluid. If I drop a small pebble of granite (a mineral) into a glass of water, it does not become soluble; it does not dissolve. Just because we can't see the Fe, Cu, Al, etc, does not mean they became "soluble" and dissolved; they are co-existing in a range not visible to the naked eye.

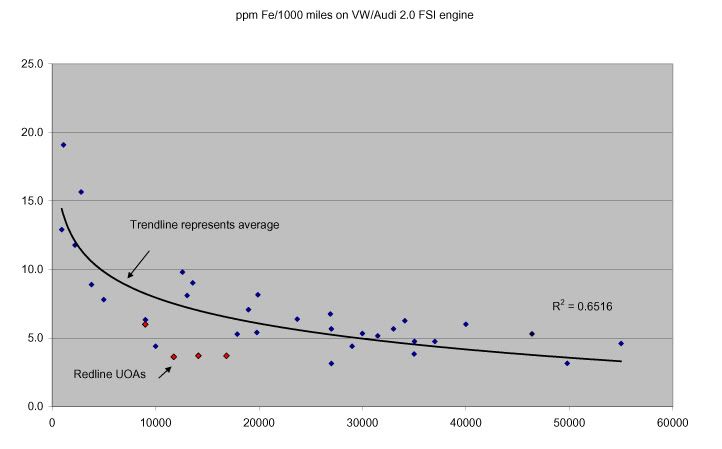

Another question I would pose is this, based upon his comments. Presuming that his position is accepted (small sized chemical wear particles are prominent because of higher anti-wear additives in "premium" oils), then would you ever see a trend downward in Fe wear in a UOA when using the RL? Conceptually, according to his theorem, you would not. As long as the anti-wear package was robust, and you continued to use said product for successive OCIs, you'd ALWAYS have high Fe, would you not? But that's not the case. Typically, UOAs will settle to a "normal" state over time, presuming you continue the consistent use of any particular chosen fluid. So while I understand what he's stating, and agree with it to some portion, I think he's being a bit short on logic. One of two things must happen: a) high initial wear from chemistry changes will occur but drop off with normalization, or b) high chemistry wear will occur indefinitely due to his claim of higher "anti-wear" chemistry. This seems counter-intuitive to utter continued high wear in a UOA and "anti-wear" all in the same breath.

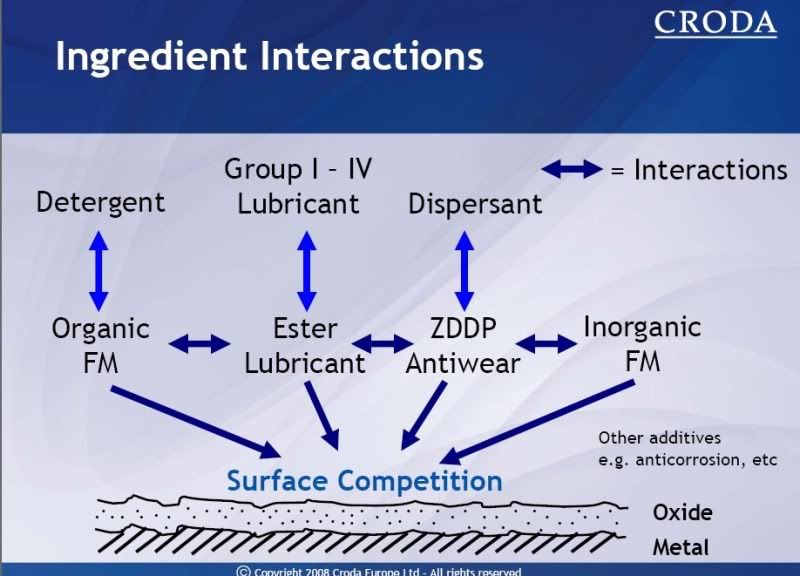

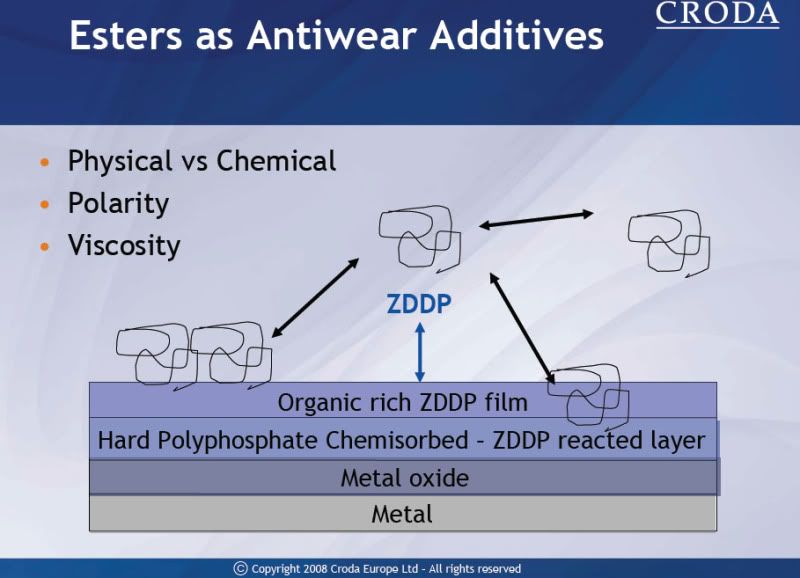

Basically, he's trying to point out that there is "small" and "big" wear, and that RL products trade off having more small "chemical" wear for less large "adhesion" wear. I guess I agree with that to some point, but not as a whole explanation. I do believe that small wear comes from chemistry, but it also comes from small abrasion, such as start up, where we mostly would agree that is likely the origin of much wear. Further, large wear can not only come from adhesion, but also from (what I will call) catastrophic events, such as large particles breaking out from mechanical issues, poor design or manufacturing effects, etc.

Roy also makes this statement "... you simply have to rely on the reputation of the marketer and whether you trust the marketer's technical expertise." So are we to believe that RL is the only lube OEM that is worth listening to? As if Mobil, Shell, Chevron, etc., have nothing good to say, and all the UOAs from those products are just bogus? I wonder, just what is Roy's experience? Is he a tribologist? A chemical engineer? A sales and marketing guy? Without being rude, I have to question his credentials; not that I'm never wrong (far from it) but he makes several misleading or flat wrong statements that are otherwise paramount to his position. To mis-spell words or make typo's is normal (I certainly do), but my objections to some of his details are factually based in logic, and I don't agree with some of his conclusions. On the surface, his reply seems laudable, but when you dig into the meat of it, it falls apart.

Traditional UOA analysis is very sound; it's used all the time, with good reason. It certainly is NOT a total view of lube or equipment health, but it is the best tool we have for a low-cost, easily applied view of the wear happening in an engine, and the host oil's ability to deal with the operating environment.

The OP has 32ppm in 8.7k miles. That's high. And if it's still that high after a few more OCI/UOA cycles, I'd say RL is likely not doing the job Roy would like for us to believe that it is doing.