Hi everyone, been a while since I've been on this awesome site. I need to start spending some more time here.

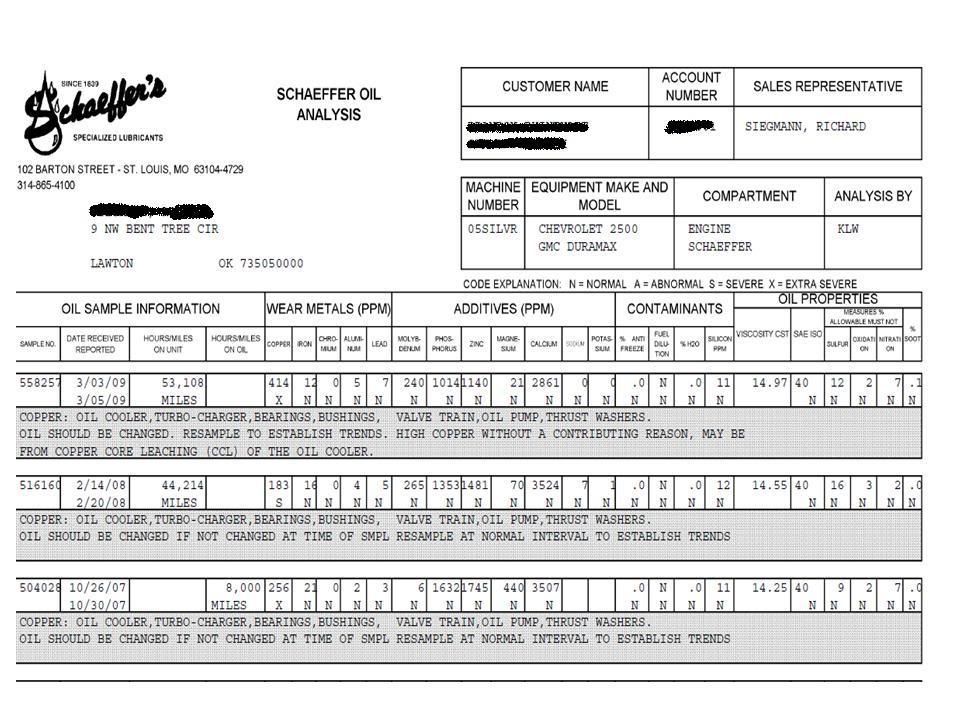

I would like to get your input on high copper readings on a '05 Duramax. The first oil analysis (10/26/07) was on whichever oil the dealer put in when the customer had it serviced. The most recent oil analysis is with 7,000 miles on Schaeffer's series 7000 15W-40. The copper dropped from 256 to 183 after changing to Schaeffer's but it is still in the severe range. High copper readings from possible copper fittings in the oil cooler like on the CAT motors - or am I off base?

I would like to get your input on high copper readings on a '05 Duramax. The first oil analysis (10/26/07) was on whichever oil the dealer put in when the customer had it serviced. The most recent oil analysis is with 7,000 miles on Schaeffer's series 7000 15W-40. The copper dropped from 256 to 183 after changing to Schaeffer's but it is still in the severe range. High copper readings from possible copper fittings in the oil cooler like on the CAT motors - or am I off base?