We all like the disgusting engine failure and sludge pics, so here you go--

From a buddy who will be racing at the SCCA Solo National Championships in Topeka next week, just rebuilt and installed his engine in the Honda S2000 racecar. Drove it only 3 miles (after idling and reving to build pressure and check for leaks/fire, etc. it developed rod knock.

#5 main bearing (which feeds #4 rod bearing) destroyed. He says it had plenty of oil pressure, no filter failure, and no evidence in the pan or oil pump of any indicators why they would fail or starve. Crank was trashed, re-machined and installed again and currently re-assembling engine this week. All clearances were triple-checked, and this is not a noob assembly.

Car with the engine out (second time)--

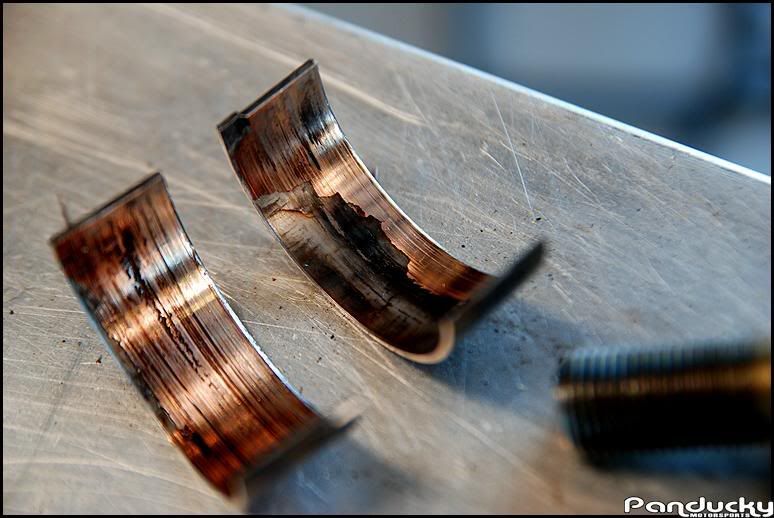

#5 main bearing--

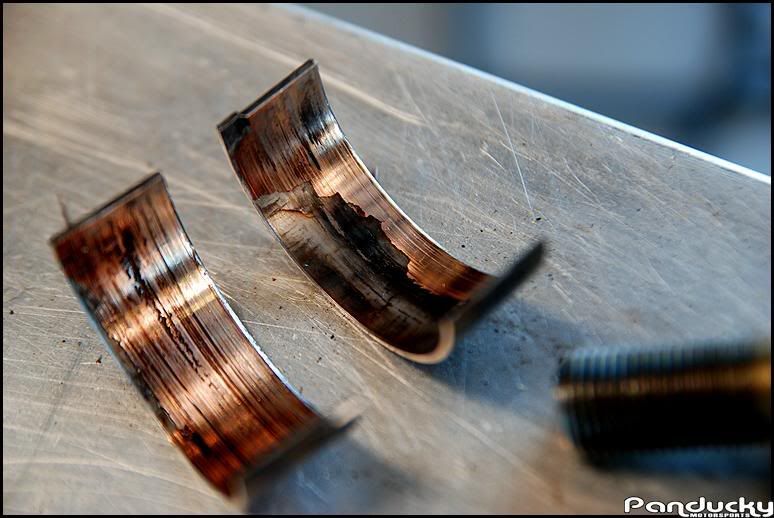

#4 rod bearings--

Okay oil nerds, let's play CSI: BITOG and see what could have caused this. Break-in oil was dino juice, some assembly lube present on important parts.

From a buddy who will be racing at the SCCA Solo National Championships in Topeka next week, just rebuilt and installed his engine in the Honda S2000 racecar. Drove it only 3 miles (after idling and reving to build pressure and check for leaks/fire, etc. it developed rod knock.

#5 main bearing (which feeds #4 rod bearing) destroyed. He says it had plenty of oil pressure, no filter failure, and no evidence in the pan or oil pump of any indicators why they would fail or starve. Crank was trashed, re-machined and installed again and currently re-assembling engine this week. All clearances were triple-checked, and this is not a noob assembly.

Car with the engine out (second time)--

#5 main bearing--

#4 rod bearings--

Okay oil nerds, let's play CSI: BITOG and see what could have caused this. Break-in oil was dino juice, some assembly lube present on important parts.